1. Classification of fluoro silicone rubber

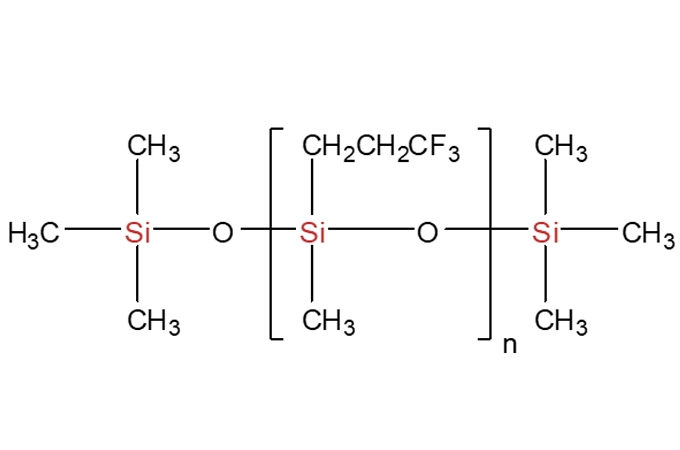

There are many types of fluorosilicone rubber. The fluorosilicone rubber produced on a large scale is mainly a polymer with γ-trifluoropropyl methylsiloxane as the structural monomer.

According to the vulcanization mechanism, fluoro silicone rubber can be divided into free radical type (vulcanized with peroxide), condensation type and addition molding. According to the vulcanization temperature, it can be divided into high temperature vulcanization type and room temperature vulcanization type, and room temperature vulcanization type is divided into one-component type and two-component type.

2. The nature of fluoro silicone rubber

The fluorosilicone rubber sheet combines the high and low-temperature resistance of silicone rubber, excellent electrical properties, resilience performance and the oil resistance, solvent resistance, saturation resistance and steam characteristics of fluoro rubber. It is currently the only elastomer that can be used in fuel media from -68°C to 230°C.

Similar to silicone rubber, fluorosilicone rubber has poor strength and low surface energy, making it a difficult-to-bond material. The introduction of trifluoropropyl, it causes difficulties in vulcanization. Therefore, it is necessary to develop a suitable formula and processing technology to improve the performance of the rubber compound. This is of vital importance to the application of fluorosilicone rubber. So it is necessary to choose a professional and reliable silicone rubber manufacturer.

Sisib is a famous silicone products manufacturer in China that has a well-equipped factory and rich production experience.

The preparation of fluoro silicone rubber compound is mainly made by mixing fluoro silicone raw rubber, crosslinking agent, catalyst, reinforcing agent, and auxiliary agent under certain conditions. After these materials are molded and vulcanized under certain conditions, fluoro silicone rubber products can be obtained.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt