Introduction

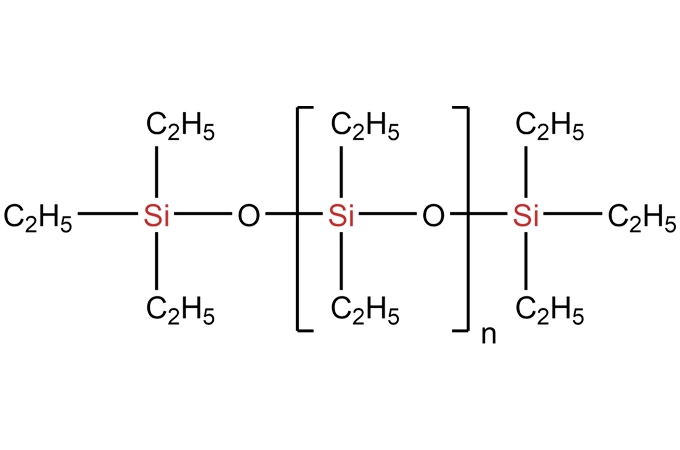

Differences between SiSiB® EF2050 PDES (Polydiethylsiloxane) and SiSiB® MF2010 PDMS (Polydimethylsiloxane):

SiSiB® EF2050 PDES are transparent liquids with a viscosity of 1.5 to 1 × 106 mm2 / s, depending on the degree of polymerization. These liquids have significantly lower glass transition and solidification temperatures in comparison with PDMS, but the effect of temperature on their viscosity is more significant. SiSiB® EF2050 PDES have a higher viscosity at 20°C than PDMS of comparable chain length. The main difference between SiSiB® EF2050 PDES lies in the extremely low pour point, which is 1.5 - 2 times lower, and reaches minus 140°С.

SiSiB® EF2050 PDES are readily soluble in most organic solvents and, unlike other organosiloxanes, are fully compatible with mineral oils, which has led to their widespread use as bases for oils and lubricants.

On the other hand, ethyl substituents and branching prevent tight chain packing, which leads to large interchain distances in diethylsiloxanes as compared to dimethylsiloxanes and to a decrease in intermolecular interactions.

SiSiB® EF2050 PDES offer the same beneficial properties as the PDMS with improved compatibility with commonly used cosmetic waxes and oils.

SiSiB® EF2050 PDES offer improved metal-metal lubrication and low temperature properties when compared to PDMS.

Typical Physical Properties

Product | SiSiB® EF2050-10 | SiSiB® EF2050-20 |

CAS No. | 63148-61-8 |

|

Color and Appearance | Colorless clear liquid |

|

Viscosity 20°C | 5~10 cSt. | 15~20 cSt |

Refractive Index 25°C | 1.435 | 1.439 |

Flash Point | 110°C | 125°C |

pH value | 6~7 | 6~7 |

Freezing Point | -140°C | -140°C |

Product | SiSiB® EF2050-50 | SiSiB® EF2050-400 |

CAS No. | 63148-61-8 |

|

Color and Appearance | Colorless clear liquid |

|

Viscosity 20°C | 40~50 cSt. | 200~400 cSt |

Refractive Index 25°C | 1.443 | 1.445 |

Flash Point | 265°C | 265°C |

pH value | 6~7 | 5~7 |

Freezing Point | -140°C | -140°C |

Product | SiSiB® EF2050-3 |

CAS No. | 63148-61-8 |

Color and Appearance | Colorless clear liquid |

Viscosity 20°C | 1.5~4.5 cSt. |

Flash Point | 110°C |

pH value | 6~7 |

Freezing Point | -140°C |

Applications

The predominant field of application of SiSiB® EF2050 PDES liquids is their use as a dispersion environment in oils and greases.

The temperature limits of operation of liquid SiSiB® EF2050 PDES are in the temperature range from minus 100°С to plus 150°С.

Depending on the viscosity, SiSiB® EF2050 PDES are classified by application as follows:

SiSiB® EF2050 PDES with a viscosity of 20 cSt or less (with glass transition temperature minus 140°C) – commonly used in electro-hydraulic pushers to drive automation mechanisms operating in the temperature range from minus 60°C to plus 100°C, for impregnating capacitors and filling piezoelectric sensors, as a component of polishing compositions, as cooling heat carriers; as working liquids in hydraulic systems.

SiSiB® EF2050 PDES with a viscosity of 40 - 50cSt at 20°C (with glass transition temperature minus 140°C), they are a high-tech organosilicon liquid, a mixture of polyethylsiloxanes of predominantly linear structure with a boiling point above 190 ° C at a residual pressure of 1.33 x 10² - 3.99 x 10² (1-3 mm Hg). Used for the manufacture of lubricants and greases.

All SiSiB® EF2050 PDES well miscible with mineral and synthetic oils and other organic products, they are used as a basis for low-temperature instrument and hydraulic fluids and oils, as a damping liquids in devices, a dispersion medium in plastic and separation lubricants, a component of polishing and cleaning compounds, lubricant in the production of synthetic fibers.

The addition of SiSiB® EF2050 PDES to hydrocarbons improves the low-temperature characteristics of the latter.

Mixtures of SiSiB® EF2050 PDES with oils have lower pour points and a satisfactory viscosity at -50°C.

SiSiB® EF2050 PDES can be mixed in any ratio with petroleum oils to improve their lubricating properties. They are good for extreme pressure and anti-wear applications. They can be used alone or as a mixes. SiSiB® EF2050 PDES liquids are biologically and corrosive inert.

Low-temperature tool oils, frost-resistant lubricants and liquids for filling hydraulic systems were created on the basis of mixtures of SiSiB® EF2050 PDES and mineral oils. SiSiB® EF

SiSiB® EF2050 PDES are used as the working oil for diffusion vacuum pumps. They differ from organic vacuum liquids in their increased thermal-oxidative stability.

Low surface tension enables SiSiB® EF2050 PDES to spread easily on skin and hair, acting as a lubricant and de-tackifying agent. Polydiethylsiloxane has a slippery, emollient, yet non-greasy skin feel with more body and cushion than Polydimethylsiloxane of equal viscosities. Unlike PDMS, SiSiB® EF2050 PDES wet pigments well, when formulating color cosmetics.

Packing and Storage

SiSiB® EF2050 is supplied in 50Kg plastic drum.

In the original unopened packaging, SiSiB® EF2050 has a shelf life of one year in a dry and cool place.

Notes

All information in the leaflet is based on our present knowledge and experience. We reserve the right to make any changes according to technological progress or further developments. Performance of the product described herein should be verified by testing.

We specifically disclaim any other express or implied warranty of fitness for a particular purpose or merchantability. We disclaim liability for any incidental or consequential damages.

Please send all technical questions concerning quality and product safety to: support@SiSiB.com.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt

SiSiB® EF2050 Technical Data Sheet

SiSiB® EF2050 Technical Data Sheet